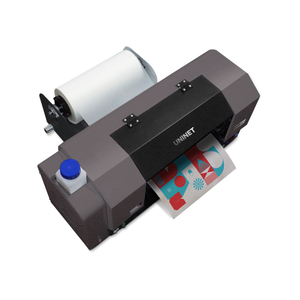

First got it to label our own products and coffee blends for retail. Started offering short run labels to our clients and it's taken off. Not a day goes by that this doesn't run

The order arrived on time, which was great! Everything was there, nothing missing. All parts are working just as they should. I'm 100% satisfied with this purchase.

The shipping and delivery were really quick, and the price was the best I found. Would recommend.